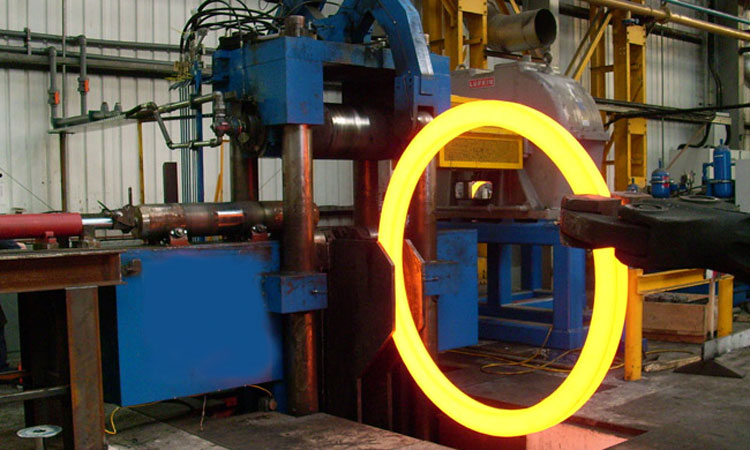

Ring rolling forgings is a process used to manufacture rolled rings with the help of rolling mills.

Precision steel rolled rings are manufactured at Angel Metal And Alloys to close tolerances which promotes minimum wastage of material and energy. The seamless ring rolling forging is produced on an automatic 4000 MT hydraulic press to form a hollow “donut”. This donut is heated above the recrystallization temperature and placed over the idler or mandrel roll. This idler roll then moves under pressure towards a drive roll that continuously rotates to reduce the wall thickness, thereby increasing the diameters (I.D. and O.D.) of the resulting ring

The seamless ring rolled forgings produces rings of a superior type, demanded by various industries. These rings can be produced in various configurations ranging from flat washer-like parts to tall and cylindrical shapes. Angel Metal And Alloys can also produce seamless rolling rings in complex, custom shapes with contours on outside & inside diameters. These seamless rolled ring forgings provide a cost-effective alternative to fabricated rings from steel plates and castings.

The diameter of the manufactured rings can range from a few inches to more than 300 inches. The requirements can vary, but as a leading forging company, we have the capacity to produce rings of the diameter and weight you require. You can even get the height of the ring to be customized,

If you are looking for ring rolled forgings, of quality that set benchmarks for the industry, contact us. We have served every industry, and our commitment to quality is evident from our list of national and international clients.

Capability to manufacture Rolled Rings

| Size Range | : | Angel Metal And Alloys state-of-the-art rolling system is capable of rolling a wide variety of ring sizes |

| Weight Range | : | 100 to 5000 kg. |

| Heat Treatment | : | Complete annealing, quenching and tempering facilities |

| Testing | : | Destructive and Non-destructive |

| Laboratory Facilities | : | Available |

| Machining | : | Available |

Forged Ring Advantages

- Achieving structural integrity

- Enabling size versatility

- Optimizing toughness

Size range

- Small or large quantities of open die or rolled rings

- Up to 252" maximum O.D.

- Up to 49" maximum face height

- Rolled ring weights to 60,000 lbs., open die weights to 300,000 lbs.

- Downstream processing such as heat treat, testing, machining, segmenting, parting or splitting can all be performed in house

- Guaranteed delivery programs